by williamsu | Jan 17, 2017 | Product News

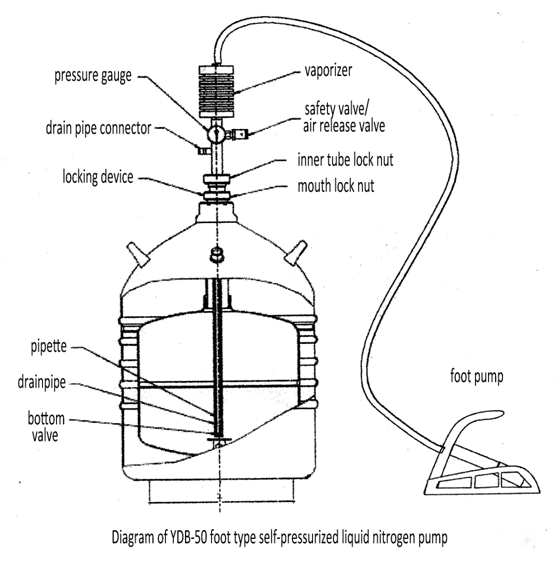

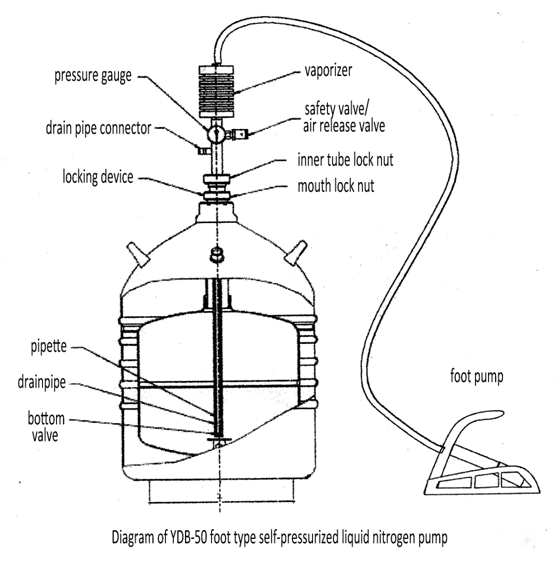

Liquid Nitrogen Pump

Auto-pressurized liquid nitrogen pump adopts the physical roperty,which liquid nitrogen is very easy to vaporization.With negative pressure suction structure,liquid nitrogen vaporise fast, which produce ultra-low pressure to drain liquid nitrogen automaticly from container.In this case, there are no disadvantages of artificial dumping and volatilizing loss.

The ideal equipment to withdraw liquid nitrogen from the container for animal husbandry, medical and scientific reasearch department.

Main Features:

Small volume, light in weight, boost fast, drain quickly, liquid nitrogen small loss, easy to operate and carry

Technical Parameters:

| Model |

Equipped neck

diameter(mm) |

Liquid discharge

pressure(≤MPa) |

Liquid discharge

speed(L/min) |

| YDB-5 |

50 |

0.04 |

≥5 |

| 80(customized) |

0.04 |

≥5 |

| 125(customized) |

0.04 |

≥5 |

by williamsu | Jan 17, 2017 | Product News

Aluminium Dewar MVE-Series Liquid Nitrogen Storage Tanks

This series is designed for those who require large capacity storage and low liquid nitrogen consumption in a convenient lightweight package.

☆ High strength aluminum alloy structure, light weight and resistant;

☆ Multi-layer thermal isolation design;

☆ Lockable cover protect stored biological samples;

☆ Protective jacket to prevent collision;

☆ Stainess steel canister with goblets for easy handling;

☆ Low evaporation loss with long holding time;

☆ 5-year vacuum warranty.

| Characteristics |

Unit |

YDS-10B |

YDS-13B |

YDS-20B |

YDS-30B |

YDS-35B |

YDS-50B |

YDS30B-80 |

| Liquid capacity |

L |

10 |

13 |

20 |

31.5 |

35.5 |

50 |

31.5 |

| Diameter of neck |

Mm |

50 |

50 |

50 |

50 |

50 |

50 |

80 |

| Wight empty |

Kg |

6.2 |

7.8 |

10.9 |

14.2 |

17.4 |

21.5 |

15.0 |

| Weight full |

Kg |

14.3 |

18.3 |

26.9 |

39.6 |

46.1 |

61.9 |

40.5 |

| External diameter |

Mm |

305 |

305 |

394 |

455 |

455 |

500 |

455 |

| Total height |

mm |

530 |

605 |

656 |

670 |

720 |

850 |

670 |

| Daily evaporation rate |

l/d |

0.15 |

0.14 |

0.16 |

0.17 |

0.17 |

0.20 |

0.24 |

| Static holding time |

D |

65 |

93 |

125 |

185 |

209 |

255 |

132 |

| Number of canisters |

|

6 |

6 |

6 |

6 |

6 |

6 |

6 |

| Diameter of canister |

Mm |

38 |

38 |

38 |

38 |

38 |

38 |

63 |

| Height of canister |

Mm |

120 |

276 |

276 |

276 |

276 |

276 |

276 |

| Number of level of goblets |

|

1 |

2 |

2 |

2 |

2 |

2 |

2 |

| Max. capacity of 0.25ml straws |

|

1788 |

2834 |

2834 |

2834 |

2834 |

2834 |

8460 |

| Max. capacity of 0.5ml straws |

|

792 |

1284 |

1284 |

1284 |

1284 |

1284 |

3624 |

| Characteristics |

Unit |

YDS50B-80 |

YDS35B-125 |

YDS50B-125 |

YDS50B-125/10 |

YDS100B-125 |

| Liquid capacity |

L |

50 |

35.5 |

50 |

50 |

100 |

| Diameter of neck |

Mm |

80 |

125 |

125 |

125 |

125 |

| Wight empty |

Kg |

19.2 |

17.2 |

21.6 |

21.8 |

29.8 |

| Weight full |

Kg |

61.9 |

45.9 |

62.0 |

62.2 |

110.6 |

| External diameter |

Mm |

500 |

455 |

500 |

500 |

560 |

| Total height |

Mm |

850 |

740 |

850 |

850 |

1110 |

| Daily evaporation rate |

l/d |

0.26 |

0.35 |

0.37 |

0.38 |

0.37 |

| Static holding time |

D |

190 |

102 |

135 |

131 |

270 |

| Number of racks |

|

6 |

6 |

6 |

10 |

6 |

| Diameter of canister |

Mm |

63 |

97 |

97 |

76 |

97 |

| Height of canister |

Mm |

276 |

276 |

276 |

276 |

276 |

| Number of level of goblets |

|

2 |

2 |

2 |

2 |

2 |

| Max.capacity of 0.25ml straws |

|

8460 |

19944 |

19944 |

20160 |

19944 |

| Max.capacity of 0.5ml straws |

|

3624 |

9048 |

9048 |

9150 |

9048 |

by williamsu | Jan 13, 2017 | Product News

Preparing pure compounds requires reliable protection of substances from contamination and some laboratory processes require safe handling of toxic materials. The SICCO Glove Box provides a cost effective and efficient tool for these and similar requirements.

SICCO Glove Box Duo 2 with Transfer Chamber, PMMA/PE

Cat.-No. V 1710-…

Aluminium frame with panels made of acrylic glass, base panel made of polyethylene. Front and back side with one door each, two pairs of opposite glove ports each with one pair of natural rubber gloves size 9, two cable lead-ins (left bottom side). Transfer chamber (right) with two doors, external door with latch to prevent accidental opening, the tray extends into the workspace with opening of the internal door for easy removal of inserted products. The tray is only operable from one workstation side (front right-hand). Work space and transfer chamber including two hose connectors for gas-filling each and appropriate tubing (2x 5 m tubing for gas-filling made of PVC and 2x 5 m aeration tubing made of PE).

SICCO Glove Box Duo 2 with Transfer Chamber Antistatic, PC ESD

Cat.-No. V 1715-…

Aluminium frame with static dissipative panels made of polycarbonate, base panel made of static dissipative polyethylene. Front and back side with one door each, two pairs of opposite glove ports each with one pair of static dissipative EPDM gloves size 9,75, two cable lead-ins (left bottom side). Transfer chamber (right) with two doors, external door with latch to prevent accidental opening, the tray extends into the workspace with opening of the internal door for easy removal of inserted products. The tray is only operable from one workstation side (front right-hand). Work space and transfer chamber including two hose connectors for gas-filling each and appropriate tubing (2x 5 m tubing for gas-filling made of PVC and 2x 5 m aeration tubing made of PE). All materials used can discharge electrostatic charging by means of a grounding cable which can be connected on the back side (connecting thread M6).

SICCO Glove Box Duo 1 with Transfer Chambers Antistatic, PC ESD

Cat.-No. V 1735-…

Aluminium frame with static dissipative panels made of polycarbonate, base panel made of static dissipative polyethylene. Front side with four glove ports and two pairs of static dissipative EPDM gloves size 9,75, three cable lead-ins on the back side (upper right, middle, left). Two transfer chambers (right and left) with two doors each, external doors with latch to prevent accidental opening, the tray extends into the workspace with opening of the internal door for easy removal of inserted products. Work space and transfer chambers including two hose connectors for gas-filling each and appropriate tubing (3x 5 m tubing for gas-filling made of PVC and 3x 5 m aeration tubing made of PE). All materials used can discharge electrostatic charging by means of a grounding cable which can be connected on the back side (connecting thread M6).

SICCO Glove Box Vitrum with Transfer Chamber, borosilicate glass 3.3

Cat.-No. V 1986-…

Aluminium frame with panels made of

borosilicate glass, front panel with two glove ports, right side panel and bottom side of base panel made of aluminium, top side of base panel made of stainless steel. Including one pair of natural rubber gloves size 9, two lead-ins for cable on the back side (upper left and upper right). Transfer chamber with two doors, external door with latch to prevent accidental opening, the tray extends into the workspace with opening of the internal door for easy removal of inserted products. Work space and transfer chamber each including two hose connectors for gas-filling and aeration and appropriate tubing (2x 5 m tubing for gas-filling made of PVC, 2x 5 m aeration tubing made of PE).

SICCO Glove box for Exhaustion, PMMA

Cat.-No. V 1988-…

Aluminium frame with panels made of acrylic glass. Base panel, integrated connector for exhaust system and closing lid made of polyethylene. Iris-Ports and cable lead-ins made of polyethylene and silicone. Two lead-ins for cable on the back side (upper left and upper right). Two crosswise slotted silicone discs each in the openings and cable lead-ins. They are staggered mounted so that the overlapping segments at the same time allow easy access to the interior space and close the openings at non-use. The Iris-Ports ensure pressure compensation through air streaming when the exhaust system is switched on. Connection to exhaust system through an integrated connector on the top panel. This connector is graded for tubes with inner diameters 100, 120, 160 and 180 mm. When working without exhaust system the opening can be closed with a lid.

SICCO Glove Box Antistatic with Transfer Chamber, PC ESD

Cat.-No. V 1992-…

Aluminium frame with static dissipative panels made of polycarbonate, base panel made of static dissipative polyethylene. Front panel with two glove ports and one pair of static dissipative EPDM gloves size 9,75, two lead-ins for cable on the back side (upper left and upper right). Transfer chamber with two doors, external door with latch to prevent accidentally opening, the tray extends into the workspace with opening of the internal door for easy removal of inserted products. Work space and transfer chamber each including two hose connectors for gas-filling and aeration and appropriate tubing (2x 5 m tubing for gas-filling made of PVC, 2x 5 m aeration tubing made of PE). All materials used can discharge electrostatic charging by means of a grounding cable which can be connected on the back side (connecting thread M6).

by williamsu | Jan 13, 2017 | Product News

Leak Tester is a professionally instrument designed for the leakage tests of packages for food, drugs, medical instruments, daily chemical products, cars, electronic components, stationeries and other industrial products. The instrument also can be used to test seal performance of specimens after falling and compression tests.

Principle

Firstly submerge the specimen in the water within the vacuum chamber, and then evacuate the vacuum chamber to form differential pressure between the inside and outside of specimen. The leakage property could be obtained by observing the steady progression of bubbles from the specimen and how the specimen expands and restores to its original shape after vacuum release.

Standards

This test instrument conforms to the standards: GB/T 15171, ASTM D3078

Leak Tester is applicable to the determination of leakage property of:

| Basic Applications |

- Glass Bottles, Pipes, Cans and Boxes

|

- Plastic Bottles, Pipes, Cans and Boxes

|

- Metal Bottles, Pipes, Cans and Boxes

|

- Paper Plastic Composite Bags and Boxes

|

- The instrument utilizes the digital preset design of vacuum degree and vacuum retention time to ensure the accuracy of test data

- Top quality parts and components made by world famous brands are used to ensure reliable overall product performance

- Specimens could be tested in the preset vacuum condition by automatic compensation of constant pressure

- Professional software supports automatic back flushing and test termination to provide a safe test environment

- The instrument is controlled by micro-computer, with LCD and PVC operation panel, which is convenient for customers to test and view test data

-

Technical Specifications

| Specifications |

MFY-01 |

| Vacuum Degree |

0 ~ -90 KPa |

| Accuracy |

1% FS |

| Vacuum Chamber Effective Sizes |

Φ270 mm x 210 mm (H) (standard) |

| Φ360 mm x 585 mm (H) (optional) |

| Φ460 mm x 330 mm (H) (optional) |

| Note: customization is available for other sizes |

| Gas Supply Pressure |

0.7 MPa (outside of supply scope) |

| Port Size |

Ф6 mm PU Tubing |

| Instrument Dimension |

300 mm (L) x 380 mm (W) x 450 mm (H) |

| Power Supply |

AC 220V 50Hz |

| Net Weight |

12 kg |