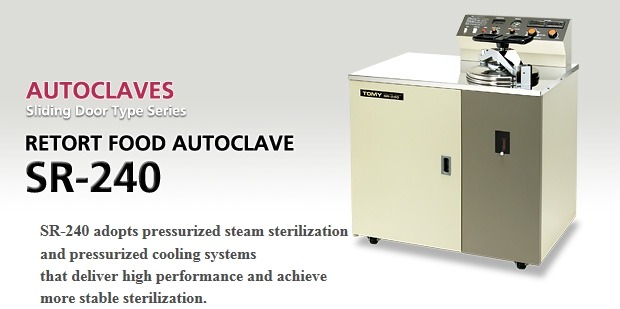

Description

Equipped with a pressurized steam sterilization system that is unavailable on a standard sterilizer.

- Retort Food Autoclave SR-240 employs a pressurized steam sterilization system that provides constant flow of steam under pressure, and allows more stable sterilization at operating temperatures in the range of 100 to 140°C.

Pressurized cooling system

- SR-240 adopts a cooling method in which water is introduced into the pressurized chamber during cooling process to prevent a sudden drop in chamber pressure or temperature which can cause damage to retort foods, including canned foods and aluminum foil packed foods.

Automatic pressurization / automatic feed water for cooling

- After turning the main power switch on and setting a sterilization time, the operation cycle progresses automatically through processes of pressurizing, sterilizing, and depressurizing by feeding water into the chamber for cooling.

Versatility for a wide range of applications

- It is also equipped with pressurized steam sterilization/boiling water sterilization system that is best suited for retort packs.

*The control panel lighting image shown above may vary from actual display.

Real time work minitor displaying 6 atatus indicators for each working process.

When the autoclave is turned on, the work monitor simultaneously indicates “Main On”. After setting parameters, the monitor displays status indicators of the current working process, including “Sterilizer”, “No Water”, “Cool”, “Exhaust” and “Finish”, which provides an at-a-glance monitoring of the operation status.

*The control panel lighting image shown above may vary from actual display.

The autoclave is designed with safety features that ensure operator safety.

Boil-dry safety mechanism

- A water level sensor is electrically responsive to the volume of water inside the chamber. If it detects low water levels, the work monitor on the control panel indicates “No Water”.

Spring safety valve

- A safety valve fitted in the front panel allows easy monitoring of its operation status. When the pressure inside the chamber is too high, the safety valve is activated to protect the operator against hazardous conditions.

Cooling water tank safety valve

- A safety valve is installed to prevent pressure buildup in the cooling water tank.

Current leakage breaker

- It quickly detects abnormalities in the electrical system and protects the operator against electric shock caused by any malfunction such as a short circuit.

Specifications

| Model | SR-240 | |

| Operating temperature range (during sterilizing) | 100 – 140°C | |

| Operating pressure range | 0 – 275kPa | |

| Maximum operating pressure | 343kPa | |

| Temperature control | Electronic | |

| Temperature display / display range | Analog / 80 – 160°C | |

| Pressure display / display range | Analog / 0 – 600kPa | |

| Heat source | 3kW electric heater | |

| Timer control | Electrically-operated | |

| Timer display | Analog | |

| Sterilizing timer setting range | 0 – 60min. 50 / 60Hz | |

| Pressurized sterilization | System | Pressurized by compressor |

| Setting range | 0 – 294kPa | |

| Pressurized cooling | System | Pressurized by compressor |

| Setting range | 0 – 343kPa | |

| Cooling | Fill the chamber with tap water | |

| Safety devices | • Empty heating prevention, • Leakage breaker, • Safety valve, • A cooling water tank safety valve or a safety valve installed in the cooling tank | |

| Malfunction prevention devices | • Low water level detection | |

| Leakage breaker | Rated breaking current: | 30A (220 / 230 / 240V) |

| Rated sensed current: | 30mA (220 / 230 / 240V) | |

| Dimensions | φ248 x 542mm | |

| Usable dimension | φ238 x 435mm | |

| Capacity of chamber | 25ℓ | |

| Chamber material | SUS304 | |

| Type / material of lid gasket | Accommodating internal pressure / silicone rubber | |

| Dimensions of main unit (mm) | 820W x 560D x 950H (Height from floor to control panel:750) | |

| Net weight | 150kg | |

| Rated Voltage | AC 220 / 230 / 240V | |

| Power input | 15A (220 / 230 / 240V) | |

| Power supply requirements | Single-phase 220 / 230 / 240V AC (50 / 60Hz) 15A or above | |

| Power Consumption (calorific value) | 3kW (2580kcal/h) | |

| Accessories | • Hose kit for supplying water 1, • Hose kit for draining water 1, • Inspection sheet 1, • Warranty card 1, • Customer card 1, • Operator’s manual 1, • Stainless basket 2 (φ224 x 181mm) |

|